Lexi Guignard

One of the most useful tools in the Makerspace is our laser cutter, a machine that uses a focused laser to cut and etch materials. We commonly cut on cardboard, wood and acrylic; we also have the capabilities to etch on glass and rubber, but these take extra precautions.

The word laser stands for Light Amplification by Stimulated Emission of Radiation. A laser is a condensed narrow beam of light in which all of the light waves have similar wavelengths. The light waves travel together in sync, which is why laser beams are narrow, bright, and precise.

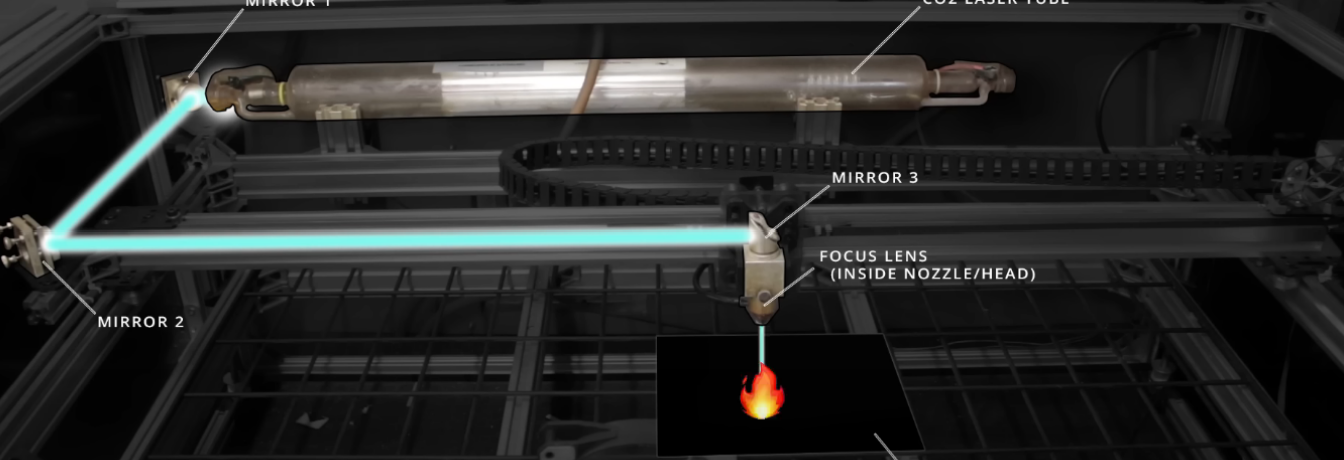

Laser cutters function differently based on the gain medium, a source or channel that amplifies light, producing a laser beam. Various materials can be used as a gain medium, including optical fibers, yttrium crystals, semiconductors, or tubes of carbon dioxide(CO2), to cut materials such as metals, wood, ceramics, and plastics. In our case, the gain medium is a CO2 tube.

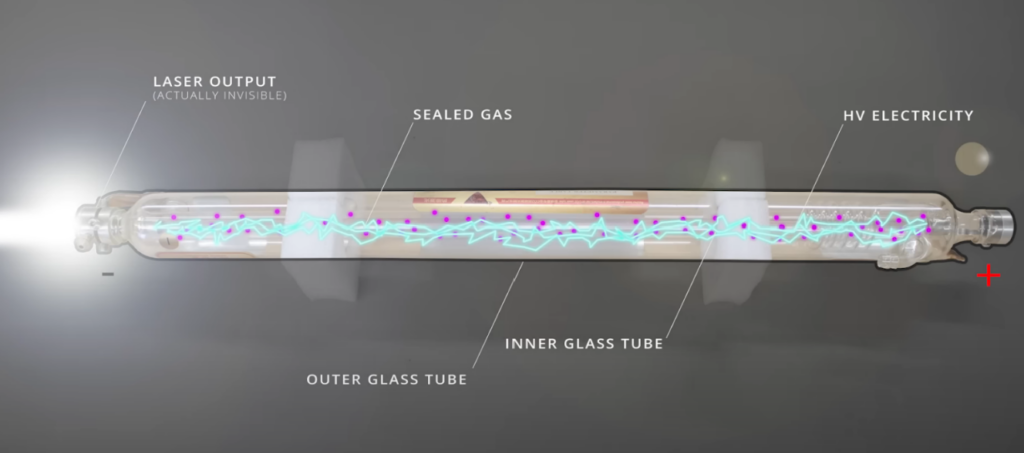

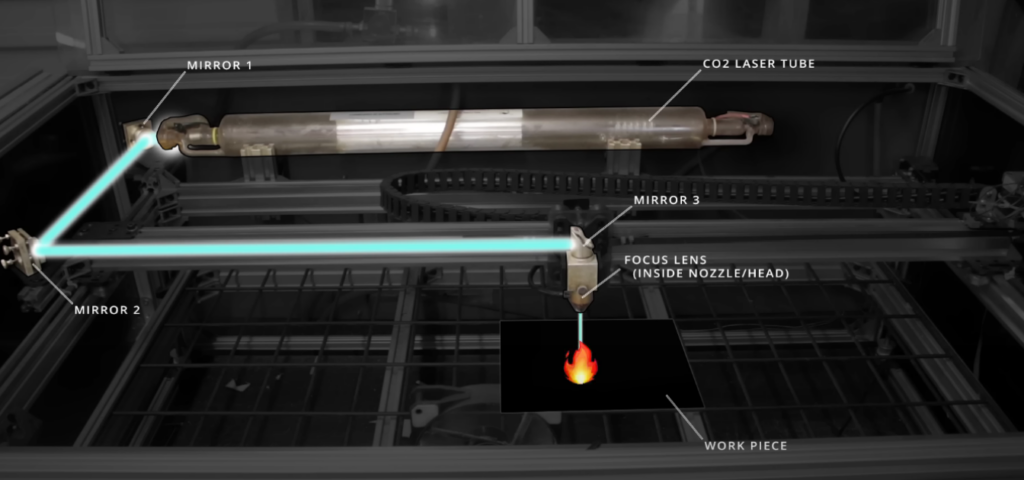

The mechanisms of a CO2 laser cutter are distinctive, using 5 mirrors in total to create the laser. Producing a laser requires at least 2 mirrors, a gain medium, and a light source. Light enters the gain medium and excites atoms until one emits a photon, setting off a chain reaction of emitted photons. These atoms bounce back and forth between the mirrors on both sides of the gain medium. One side has a partially reflective mirror, allowing photons to escape and form the laser beam.

The first external mirror aims the laser from the CO2 tube directly down the Y axis of the working area and meets the second external mirror that reflects across the X axis. The third external mirror directs the laser down into the focus lens, condensing the photons to a precise point, also known as the focus point, where the power and accuracy of the laser is greatest. The workpiece cannot be too far from the focus point or it will not cut properly.

The laser cutter takes the place of many tools, including saws, X-acto knives, wood burners, scissors, drills. Working by hand means the measurements will not be as exact as they could be. The laser cutter can cut and etch precise designs at a much faster rate, allowing the Makerspace to be a center for creativity!

Sources:

- “4 Types of Laser Cutters That You Need to Know.” Www.xometry.com, www.xometry.com/resources/sheet/types-of-laser-cutters/.

- Further Fabrication. “How CO2 Laser Cutters Work and …Why You Might Want to Build One!” Www.youtube.com, 19 Apr. 2019, youtu.be/t4BfQGhhbOQ?si=VQpvpgvg-pARYil7.

- NASA. “What Is a Laser? | NASA Space Place – NASA Science for Kids.” Nasa.gov, 2017, spaceplace.nasa.gov/laser/en/.